ACEiT® Blue: Proprietary Surface Finishing and Curing Agent

ACEiT® Blue is a proprietary surface finishing and curing agent especially designed to work in conjunction with ACEiT® additives, and specifically engineered for low-slump compactable concrete products such as Roller Compacted Concrete and Cement Treated Bases. Its use can also be beneficial in Conventional Ready Mixed Concrete applications. ACEiT® Blue is a low viscosity liquid manufactured in Wichita, Kansas. ACEiT® Blue produces an easy-to-spray liquid that can be uniformly applied. ACEiT® Blue is relatively odorless and tasteless, is inert and non-reactive, blue coloration dissipates upon exposure to UV light where at such time it becomes clear and transparent. ACEiT® Blue does NOT form an indefinite film, so it does not prohibit the bonding of other materials such as striping paints or sub sequential layers of concrete. ACEiT® Blue is sold and typically shipped in 275-gallon plastic totes, but can be packaged in alternative customer specified volumes.

When sprayed in a mist to the surface of the concrete, ACEiT® Blue extends the finishing and working time, reduces friction, workability, and overall performance of the RCC pavement. The proprietary blend of highly concentrated Rheology Enhancing Ethers, Non-Surfactant Surface Tension Reduction Compounds and Film Forming Water Retention Extracts that when activated by mechanical energy ACEiT® Blue will assist ACEiT® Plus in the generation of a finishing paste that closes the surface of the RCC mat, increases surface durability abrasion resistance, reduces permeability, increases freeze/thaw durability, reduces loss of moisture through evaporation, extends working time, extends the life of fresh joints, and creates surface conditions conducive to traditional concrete finishing techniques that are indistinguishable from conventional concrete.

At its typical dosage rate, ACEiT® Blue also functions as a curing agent for the RCC because of its proprietary bonding to the water molecules that prevent them from escaping the pavement and allowing for full hydration of the cement. This action helps promote superior strengths and surface durability in the RCC, and also reduces the frequency of flash setting in low slump concrete mixes and premature shrinkage cracking-especially in high temperature and high wind placement conditions.

ACEiT® Blue can assist in providing a desired textured finish, i.e. broom finish without roller or other marks; mitigating the need to grind or repair areas that placement conditions would not allow with the use of rollers when placing conventional RCC.

Dosing of the ACEiT® Blue finishing and curing agent is typically one gallon per 100-200 square feet. The agent is typically applied by use of a mechanical pump from a bulk tank, or through a portable hand sprayer. No special tanks, hoses, or spraying nozzles are required. ACEiT® Blue finishing/curing agent’s dose is subjective to the mix design’s gradation and cement content, and weather conditions. It is not recommended to have ACEiT® Blue pond or applied so heavily that it runs on the surface. A fine mist is recommended and with our patented “Blue” color, visual coverage of the surface area is possible. ACEiT® Blue can also be added through the water system on compaction equipment that have water dispersion capabilities and the water distribution system on trowel machines.

ACEiT® Blue should be stored in an area that prevents freezing. Freezing will cause segregation of ACEiT® Blue while it can be reconstituted by warming and recirculation. Typical shelf life is approximately 6-12 months in factory container.

ACEiT®

Compacted Concrete Paving “The Improved RCC”

A new pavement for a new millennium

Faster installations, lower initial costs, lower life cycle costs, and the most sustainable available. We construct long-lasting pavements with the highest quality.

In today’s environment how do we add value, longevity and strength to a project, while at the same time reduce construction costs, schedule and maintenance expenses for the customer? The answer is simple… by adding the engineering and costs benefits through the use of cement treated bases and Compacted Concrete Pavement (CCP). Andale Construction is able to accomplish these goals for you.

CCP (Compacted Concrete Pavement) is an advanced form of RCC (Roller Compacted Concrete). CCP differs from RCC in that it requires less compactive effort, can be finished in texture and is easier to construct.

CCP has zero slump and a similar unit weight as a typical RCC mix and is produced and constructed with the same specifications. The major differences in construction are that CCP has a longer “fresh” or “green” period and requires little or no rolling. Another distinct difference is that we do not finish the surface with a roller. In its place we use a trowel machine to make the surface more uniform and consistent. Using our patent pending finishing process, along with the ACEiT admix, we can now construct a textured surface on the pavement that is indistinguishable from conventional concrete.

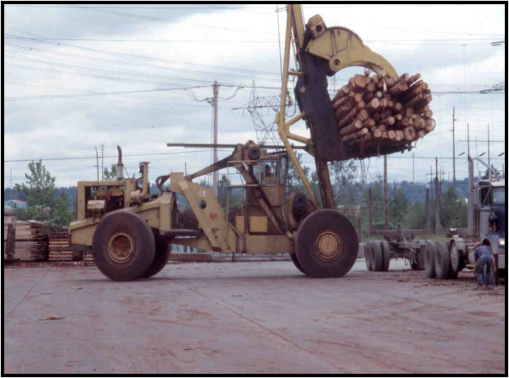

RCC became well-known in Canadian log sorting yards in the early 1970s.

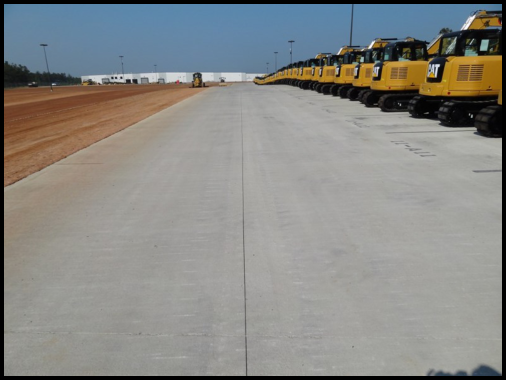

RCC was recognized as the “go-to” pavement of choice in intermodal and port facilities, as well as in military installations for its speed of installation, reliability, consistent mass production, resilience to a wide variety of weather conditions, heavy repetitive loading without premature failure, and lower cost.

Now the next step in the evolution of RCC is upon us. RCC has taken a technological leap in it’s appearance, constructability and engineering properties. RCC has evolved to CCP (Compacted Concrete Pavement) and its uses are growing by leaps and bounds.

CCP (Compacted Concrete Pavement) can make your dollars go much farther when compared to traditional pavements. A properly designed CCP section with an appropriate subgrade can easily achieve several decades of service without any maintenance and will not be affected by an increase in daily loading or overall loading.

CCP is the only pavement in which you can place up to10” in one pass and allow traffic on the roadway within days of installation. Superior compressive and flexural strengths are unmatched with conventional pavements. Daily production quantities of up to a half mile by 24 feet wide are common.

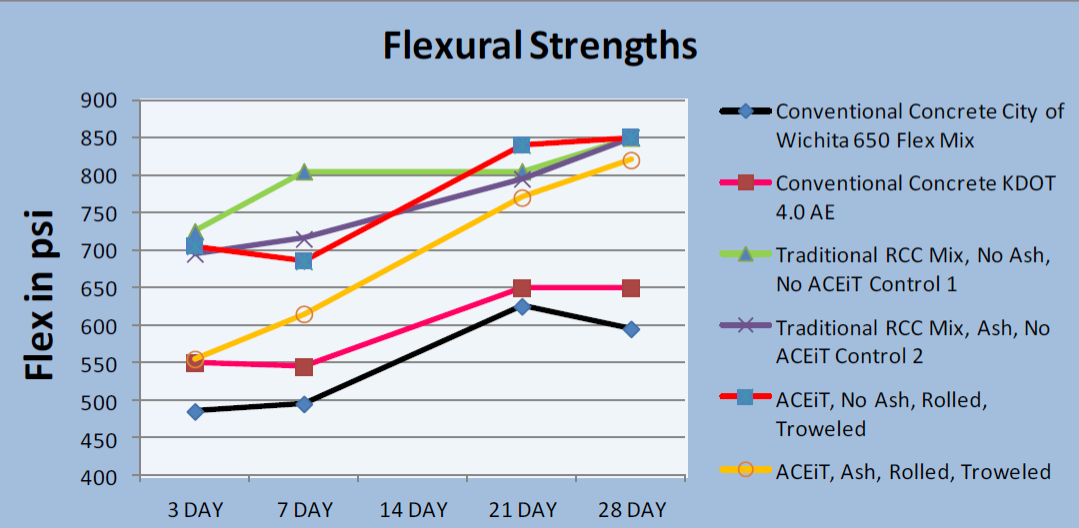

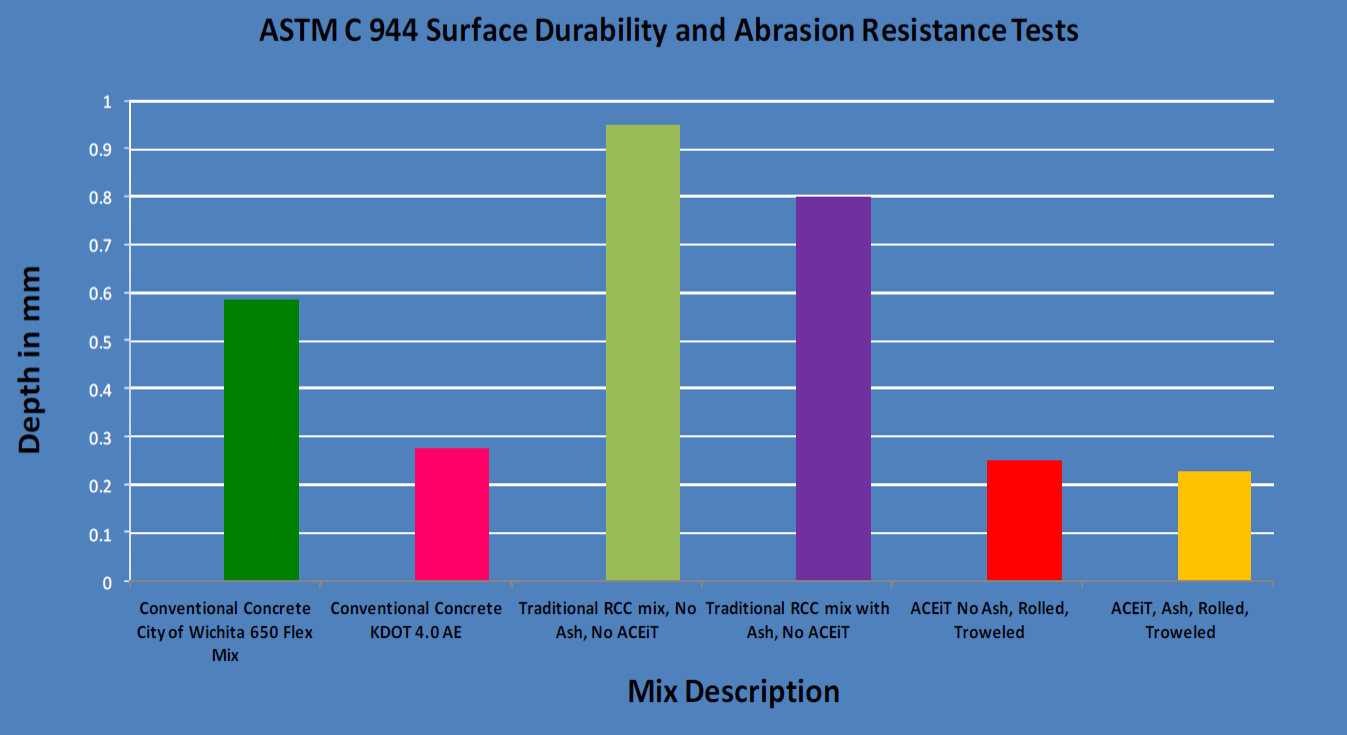

The graph below shows the surface durability/abrasion results from running ASTM C 944-Standard Test Method for Abrasion Resistance of Concrete or Mor-tar Surfaces by the Rotating-Cutter Method. The University of North Carolina-Charlotte ran these tests in 2015. The tests verified ACEiT and troweling had positive affects on the surface of the pavement. CCP with the ACEiT additive in-creases the surface durability and resists abrasion by a factor of over 200%, and is comparable or better than conventional concrete mixes. This is beneficial for the industrial use of CCP as well as CCP in Northern climates where the pavement may be exposed to freeze, thaw and snow plowing. It is also a great indication for long term serviceability and high durability in harsh environments, as well as abusive use.

- Local Streets and roads and new sub-divisions

- Reconstruction of old deteriorated roads

- Commercial Developments

- Industrial/Manufacturing Plants

- Military Facilities

- Intermodal Facilities

- Port Terminals

Lower Heat Island Effect. It’s a cooler pavement.

Greater Solar Reflectivity, therefore you need less night time lighting.

Ability to use recycled aggregates and more fly ash than conventional concrete.

Less initial cement than conventional concrete which lowers carbon foot print to construct and maintain. (No repetitive milling and repaving).

We can achieve up to 8 LEED points by using CCP.

Based On:

- Twin Shaft Mixer or Pug Mill Plant

- High Density Screed Paver

- Appropriate Mix Design

- Smoothness (IRI)

- Concrete Density (for durability, frost, permeability)

- Concrete Strength (for fatigue)

- Uniformity of Product (Density, Strength)

- Surface Texture (for smoothness, appearance, friction):

- Class 1— High Specification

- Class 2—Moderate Specification

- Class 3— Low Specification

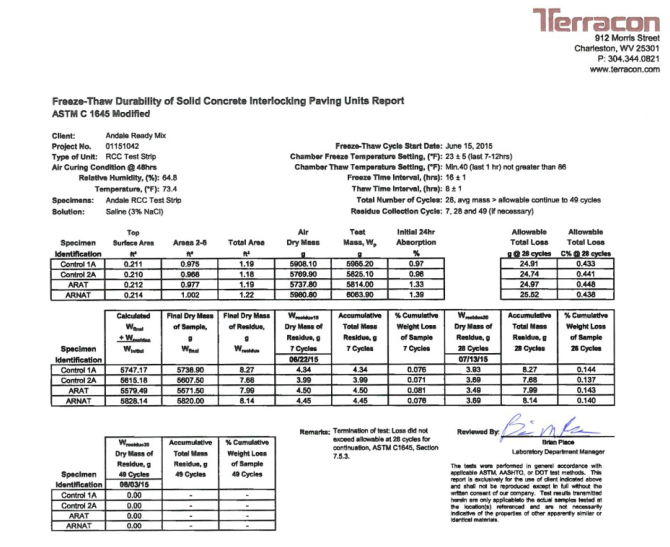

One of the tests that we chose to run on CCP with ACEiT was ASTM C 1645 -2006 standard test method for freeze-thaw and de-icing salt durability of solid concrete interlocking paving units. This test was chosen because RCC or CCP is more closely related to interlocking pavers be-cause of the gradation and low slump characteristics of the pavers. As you can see, the de-icing salts and freeze thaw cycles have little affect on CCP.

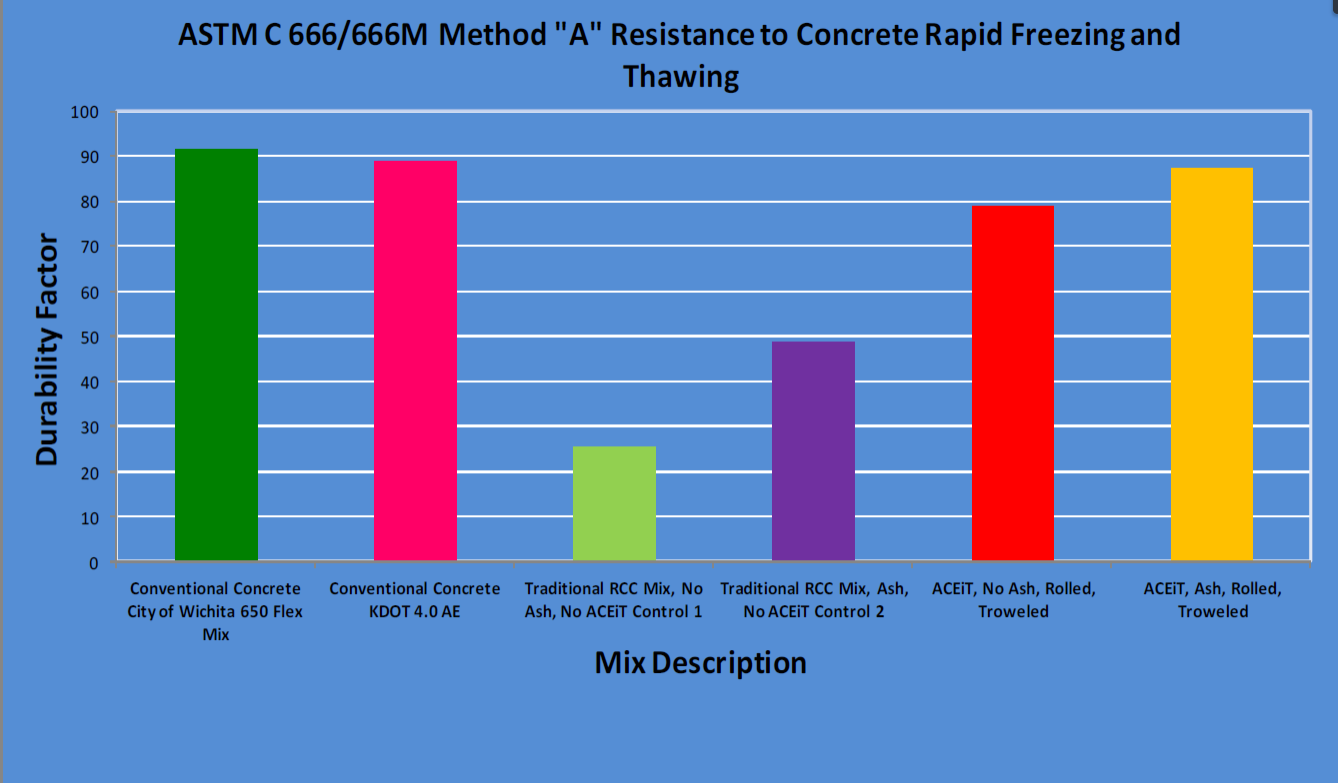

ASTM 666 is not typically used to test the freeze/thaw durability of a CCP pavement. RCC traditionally has an inherent lower water and cement content and has historically not passed the ASTM 666 test with a durability higher than 60. As you can see from the results below, ACEiT improves the freeze/thaw durability immensely and CCP performed extremely well. This is unprecedented in the RCC industry and proves even further that by selecting an appropriate mix, we can take RCC to the next level and have a pavement that is not only stronger and more durable, but also more resistant to the most severe climates.

For more information on how Andale Construction can help build a better project for you and add value to your site, please contact us for additional information, a quote, or project evaluation

We provide the following services:

- Consulting

- Design Build Services

- Super Slurry Cement Stabilization

- Concrete Paving

- Complete Civil Construction Services

ACEiT® Technical Date Sheet

ACEiT PLUS Description:

ACEiT PLUS is a proprietary concrete additive, specifically engineered for low-slump/high-strength compactable concrete mixes and cement treated bases. ACEIT PLUS is a blended dry powder additive that is odorless, tasteless and bio-degradable. It is comprised of a unique blend of concentrated uniquely processed ethers that are capable of:

- Arresting and controlling phase II cement hydration temperatures

- Decrease the quantity of mixing water (water/cement ratio)

- Enhance workability of harsh concrete mixtures

- Suspend cement particles that remain in a cohesive matrix

- Activate and change cement paste rheology via kinetic energy created by the placement machine.

The combination of these attributes provides the user with a more workable mix, easy to place and finish, low slump concrete mixes, that become easier to mix, place, compact, and allow for a finished and tooled surface.

ACEiT PLUS is distributed into the mix via a specialized dispenser that is computer rate controlled to dispense the appropriate amounts at the desired times and rates. The concentrated product is wetted and atomized at the point of the ACEiT PLUS discharge into the concrete mixing chamber. In the case of using a twin shaft concrete mixer, ACEiT PLUS may be added dry by incorporating preweighed water dispersible bags, or a dry material dispensing feeder.

- A trowel brush finished surface

- Smooth level surface without roller marks

- Increased transportation time—- 2 to 5 hours without loss of moisture

- Final set period of cement hydration begins to occur after ACEiT PLUS is mechanically activated

- Structural fibers (steel, glass or polypropylene) can be incorporated for joint load transfer

- Production of concrete does not need to occur on job-site

- Warping and Curling is mitigated (curling is a persistent problem with dense concretes)

- Labor force significantly decreased because workability is increased and set times are extended

- Extended pot life diminishes level of placement urgency, because concrete containing ACEiT PLUS can remain fresh for greater periods of time than that of conventional mixes

- Multi-lift bonding is achieved much easier and successfully accomplished without bonding agents

- Increased cement paste workability and cohesiveness. The use of ACEiT PLUS allows the user to achieve total mix workability, a tighter surface, and is affected less by the environment than traditional low slump mixes.

- Lower water demand to achieve similar density

Dosage Rates:

Typical dosage rates for ACEiT PLUS are from .002 to .004 pounds per total weight of cementitious material. EXAMPLE: .002 X 450 (pounds cement) = 0.9 pounds ACEiT PLUS per cubic yard of concrete. For the most accurate and uniform dosing; an ACEiT Industries, Inc. approved dispensing system should be utilized.

Storage/Handling/Packaging ACEiT PLUS:

It is recommended that ACEiT PLUS should be stored in a moisture free containment area and has a shelf life of over one year; if kept throughout that time in a dry/moisture free environment.

All measures should be taken to insure that packaging is not damaged prior to immediate use of the material and that it does not become contaminated with other materials.

ACEiT PLUS is typically packaged in 40-pound poly lined bags. 2,000-pound Super Sack packaging or other sizes are available upon request.

For additional information please visit our web site at: www.aceitusa.com or call (316) 832-0063